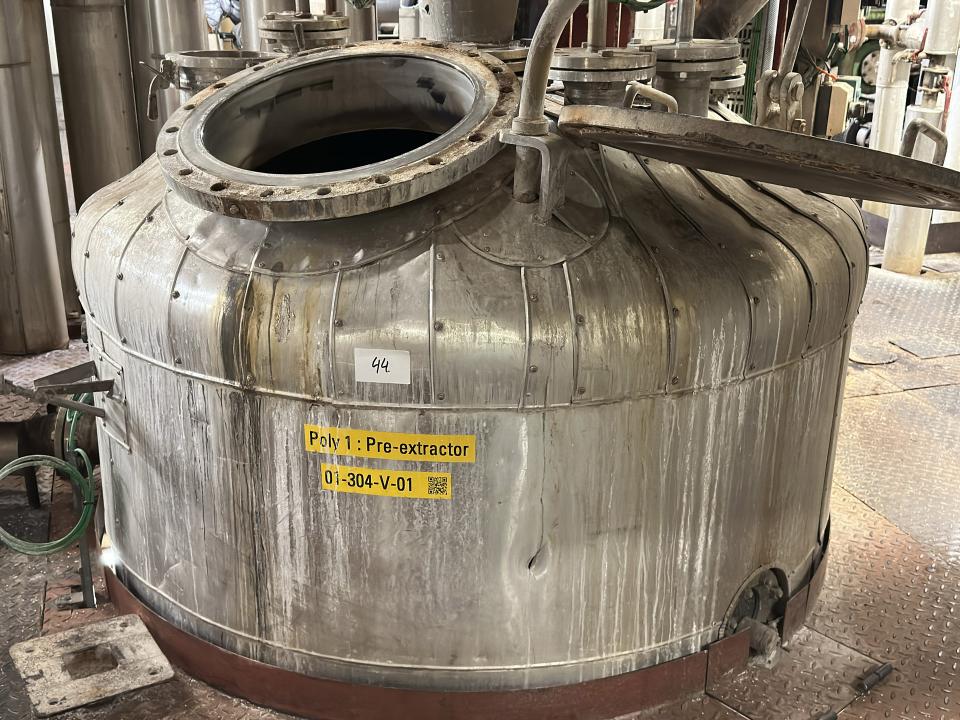

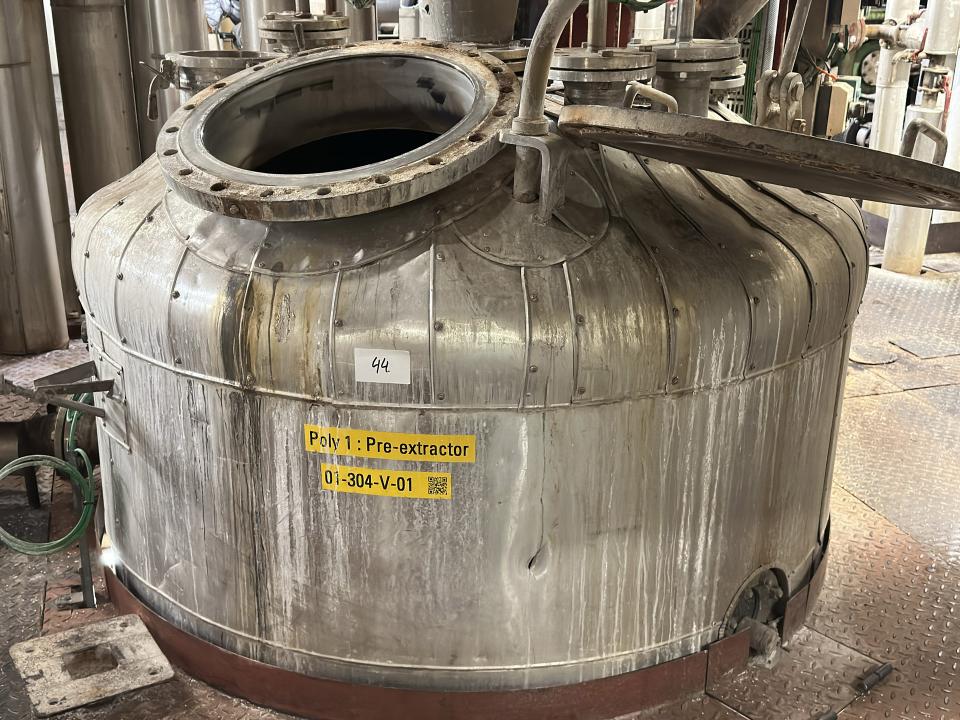

Pre-extractor

Extraction SystemsSKU: SSMINYO1-00000462

Capacity : 8650

Zimmer® is a name that resonates with German engineering excellence and industrial legacy. Known for its specialised machinery in synthetic fibre production, Zimmer equipment has powered textile and polymer manufacturing facilities across the globe for decades. At SSMI, we offer select used Zimmer equipment from recently decommissioned industrial sites—machines that were fully operational until dismantling and ready to be repurposed in new production environments.1

Choosing Zimmer means investing in robust, proven solutions designed for long-term performance. Choosing SSMI means doing so sustainably and with complete transparency.

These machines are sourced from real-world operations and come with traceable usage histories, giving you confidence in their performance.

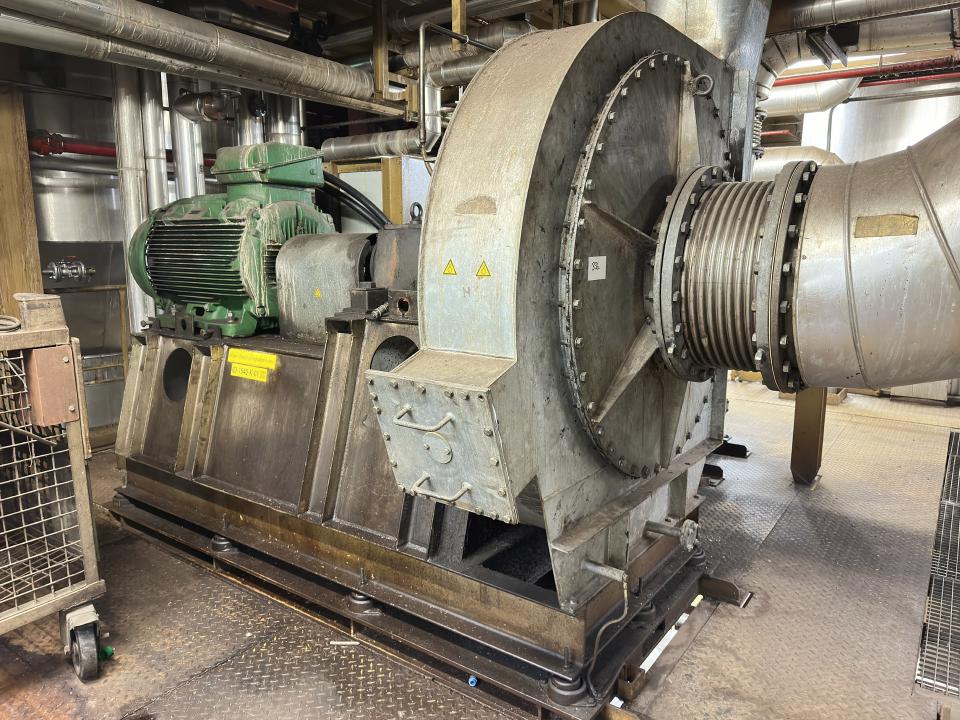

SKU: SSMINYO1-00000382

flow volume: 4.977 m3/h; pressure: 190mBar; power: 48.7 kW; fan speed: 2.955 RPM; motor: 45kW; V = 380;

SKU: SSMINYO1-00000385

This 1993 Zimmer® Alb Klein tank drying tower delivers proven industrial durability and high-capacity performance, rated at 84 400 m³/h. Originally deployed in synthetic fibre and polymer processing, it's fully operational and primed for repurposing in new installations.

It's weight is net!

SKU: SSMINYO1-00000380

V = 14560 m3/h / A = 250 - 300Bar / T = 10 - 70°C / KW = 123 - 149 / U/h = 2,980;

SKU: SSMINYO1-00000452

Test pressure: ATM; max operating temperature: 130°C; Capacity : 1500

SKU: SSMINYO1-00000459

This 1993 Zimmer – Apparatebau Crimmitschau Nitrogen Cooler is a specialized industrial chiller designed for controlled thermal management in pharmaceutical, cosmetic, and chemical processing environments. Built to operate under high temperatures and moderate pressure, it's ideal for applications requiring precise nitrogen-based cooling.

Operating pressure: 06-07Bar / Temperature: 60 - 140°C; Capacity : 551

This unit is suited for process cooling where elevated operating temperatures and gas-based systems (like nitrogen) are part of critical thermal workflows. A practical, cost-effective option for facility upgrades, pilot plants, or spare unit deployment.

Industry-proven engineering from one of Europe’s most established fibre machinery manufacturers

Reliable and rugged machinery built for continuous industrial use

Sustainable procurement—machines that support the circular economy

Cost-efficient alternative to new equipment with shorter lead times

Offered as-is with full transparency—no refurbishment, no surprises

Direct sourcing from dismantling projects across Europe

Reliable sourcing – All machines come from operational industrial sites.

HSE-compliant execution from project intake to final transport

Transparent transactions – No hidden costs, clear equipment specifications.

End-to-end project support for buyers and facility owners alike

Founded in 1949 in Offenbach, Germany, by engineer Hans Joachim Zimmer, Zimmer® quickly became a leader in the design and manufacture of equipment for synthetic fibre production. One of its notable innovations was the electrically heated star melter (“Sternschmelzer”), which revolutionised polyamide fibre spinning systems. By the late 1950s, the company had expanded internationally, supplying major polymer projects across Europe.

By 1960, Zimmer held over 327 global patents, with exports accounting for 90% of its business—testament to its influence and demand.

1963: Following the death of founder Hans Joachim Zimmer, the company was acquired by Vickers Ltd., a prominent British engineering firm.

1967: Zimmer was integrated into Davy Corporation, another major UK-based engineering conglomerate.

1991: German industrial group Metallgesellschaft AG acquired Zimmer, merging it with its subsidiary Lurgi AG, further expanding its reach in chemical and process engineering.

2007: The Lurgi Group, including Zimmer, was acquired by Air Liquide.

2015: Zimmer became part of Technip, a global leader in project management and engineering.

2021–Present: After the spin-off of Technip Energies, Zimmer’s polymer technologies continue to be offered under the Technip Energies brand, maintaining its focus on polyester and polyamide process technologies.

Zimmer’s evolution reflects not only its resilience but also its lasting relevance in the global industrial landscape.

synthetic fibre spinning, texturising, and drying

emulsifying, mixing, and heat-integrated plastic processing

Zimmer® equipment stands as a hallmark of durability, precision, and legacy engineering. At SSMI, we provide a carefully curated selection of these historic machines—backed by our commitment to circularity, quality, and operational value.

👉 Get in touch with us today to enquire about Zimmer equipment in stock, or to discuss how we can assist with your factory’s downscaling, dismantling, or resale needs. Let’s give legacy machines a new lease on life—together.

|

Michael Kreher |

|