Power Heat Set / Yarn processing

Various Yarn ManufacturingSKU: SSMINYO1-00000324

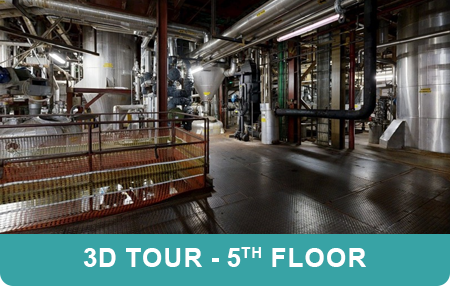

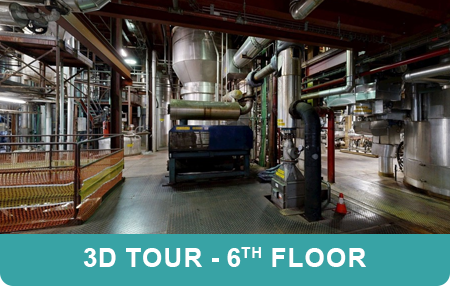

Proven Yarn Heat-Setting Performance – Gilbos GVA 5000 with NIDD C Winder (2007)

The Gilbos GVA 5000 offers a robust and reliable solution for yarn heat-setting, making it ideal for processing synthetic yarns used in carpet manufacturing and other textile applications. Built in 2007, this line includes a Gilbos NIDD C winder (model 99-2456), known for its high-speed winding and precise tension control.

Designed for efficiency and durability, the GVA 5000 supports continuous production with minimal operator intervention. It's a dependable solution for textile facilities looking to expand heat-setting capacity without the cost of new machinery.